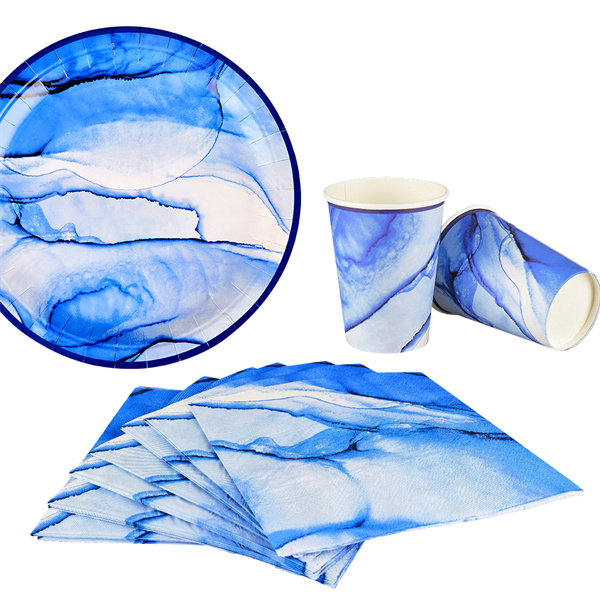

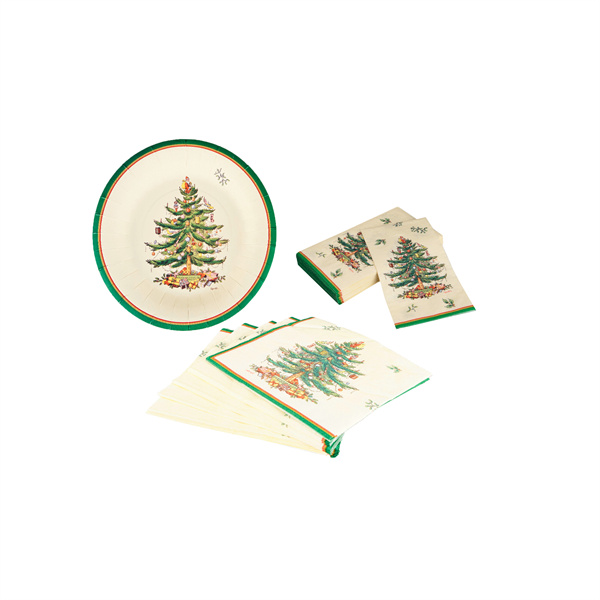

Environmental protection and convenient custom pattern printing disposable paper lunch plate

Why Choose Paper Plate

awareness, more and more people refuse to use polystyrene fast food boxes, paper plates came into being.

"Paper instead of plastic" naturally became the first to think of the program. Many people like to use paper plates when they eat. They find it very convenient. Besides, there is no need to wash dishes after using paper lunch plates, which can save a lot of time.

A lunch plate, also called a luncheon plate, is a plate that is smaller than a dinner plate but larger than a salad plate

. It usually measures 8.75-9.5 inches in diameter

. A dinner plate is traditionally 10-10.75 inches in diameter, but some restaurants may use larger plates up to 12 inches

The tableware made by this method has been dubbed as "environmental protection product" because of its non-toxic, harmless, easy to recycle, renewable use, degradable and other advantages. It is a good alternative technology in comprehensive evaluation at present.

So how are paper lunch plate produced?

Firstly, we will make plates based on the customer's desired patterns.

After printing, we will apply oil or film according to the customer's needs, and then send them to the indentation workshop for cutting.

We will separate the paper plate blanks and edges, and send the separated paper plate blanks to the molding workshop.

Next, heat the mold, wait for the temperature to reach the standard value, and start the machine. The paper plate blank will be transported to the mold by the conveyor belt.

The hot mold will clamp the papery plate blank up and down, and the high temperature will cause the paper plate blank to form a fixed shape.

This completes the production of the paper lunch plate.